Design and production of optical components

and systems for special use:

- Testing of components and systems in high vacuum chamber

- Stellar navigation

- Alignment diagnosis

- Navigation systems

- Multispectral vision systems

- Head-up display systems

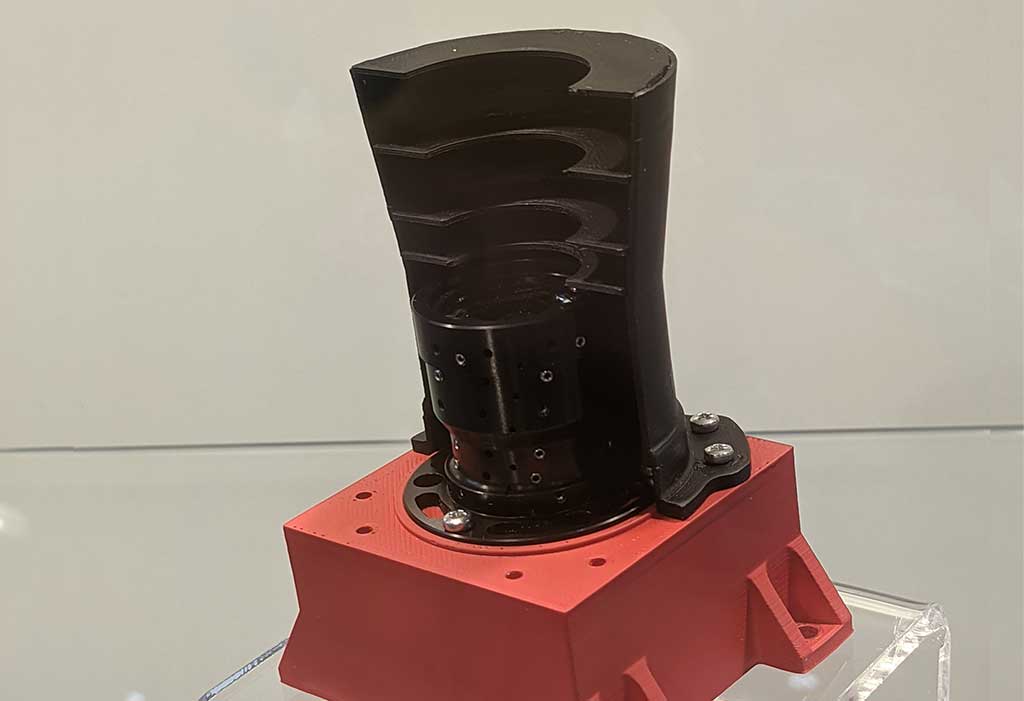

Startracker

Lens made for being mounted on satellites as an eye for stellar navigation systems. It complies with ECSS specifications for flight systems.

Monolite Mirror

Monolithic parabolic mirror in aluminum alloy made with single point diamond turning process.

Reference cube

Monolithic cubes with 5 orthogonal faces within 5 arc seconds with or without reflective coating. It is used as reference mirrors for the alignment and monitoring of systems in flight or for tests in thermo-vacuum chambers.

How we work

Our priority is to guarantee our products, and we do it by taking care of every single step:

- We carry out projects based on customer specifications.

- We support the customer for a proper choice of the requirements and the best cost / performance output.

- We take care of the prototyping and fine-tuning phase of the production processes, in order to make the product reliable and performing.

- We ensure the continuity of series production for long periods without the risk of product obsolescence and unavailability of components.

From design to production in a single solution

Technical dialogue

Our technical office supports the customer from the definition of the project features t to the choice of the technical solutions to be used.

Quality assurance

We follow all the phases of the project in our factory, from engineering to production. We are thus, able to ensure the compliance of the delivered products to the specifications agreed with the customer in the design phase.

Internal production

We carry out the production internally, up to assembly and final testing. Thus we keep control over the entire process and we guarantee consistency in timing and costing.

Support in the development of ideas

As manufacturers and designers, we are able to guide the customer towards the most suitable manufacturing solutions for the industrialization of production from the earliest stages of the project.

After sales support

We follow the customer in his experience of use, guaranteeing the availability of products over time. We plan project updates and we agree modifications with the customer to improve the effectiveness of the solution in its operational context. We make spare parts available and we carry out repairs throughout the life of the product.

Vertical integration

Pecchioli Research is the single interlocutor for the design and supply of customized optical solutions. Our internal capacity for design, planning and technical implementation qualifies us as a technical partner specialized in optical solutions for industry, scientific research and defense.